Precious Metals Trading: Technology and Operational Details of Ruthenium Dioxide Recovery

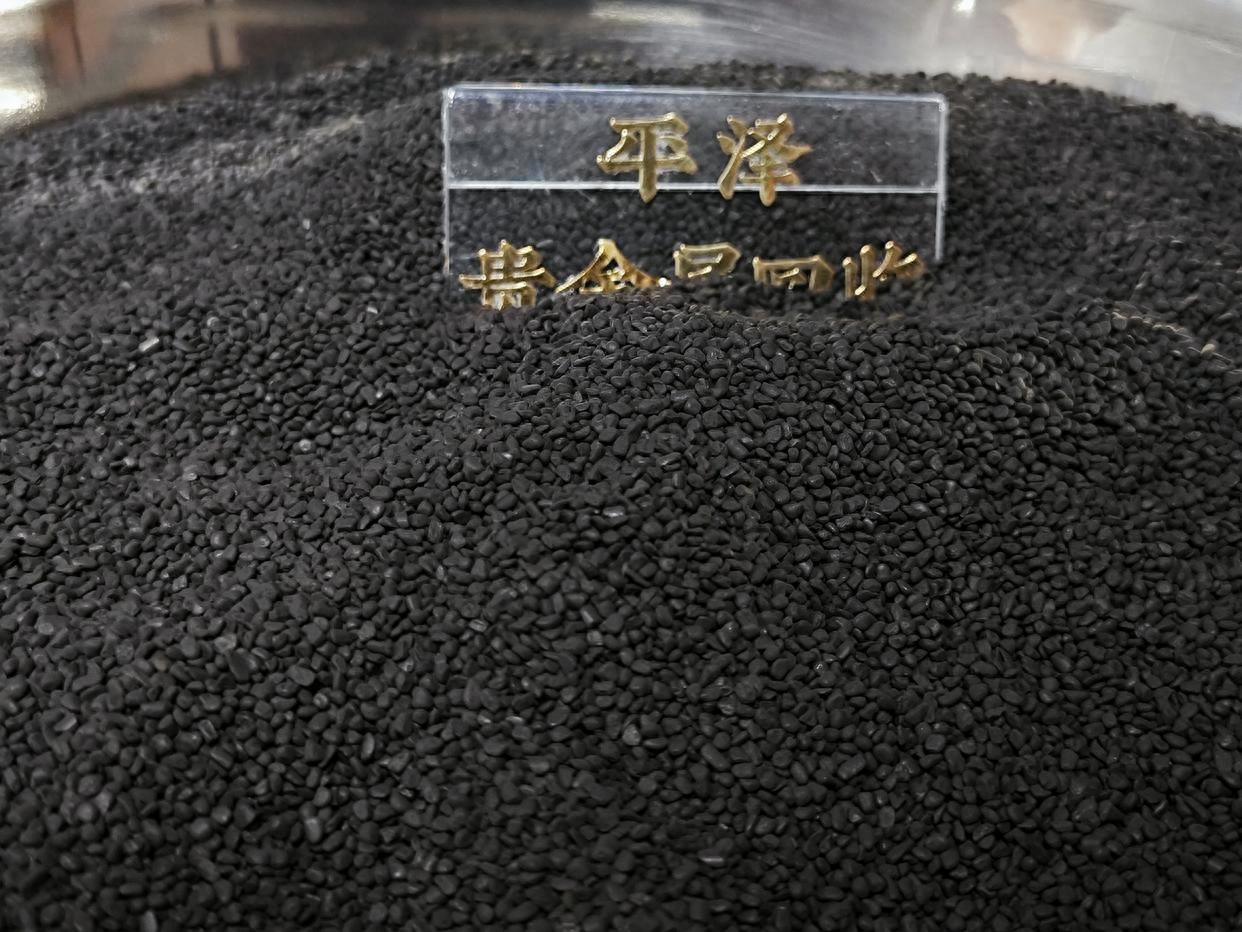

Ruthenium dioxide is an inorganic compound with the appearance of a dark blue powder. It is primarily used as a chemical catalyst and is an important raw material for the manufacture of resistors and capacitors. After a brief introduction to ruthenium dioxide, today we will discuss the recovery of ruthenium dioxide in detail.

1 Picture Gallery: Precious Metals Trading: Technology and Operational Details of Ruthenium Dioxide Recovery

.jpg)

It is known that ruthenium dioxide has a very high ruthenium content, generally over 65%. Therefore, its recovery is simpler compared to other ruthenium-containing compounds. The recovery of ruthenium dioxide typically involves chemical solvents, such as strong acids or bases, because they can effectively separate ruthenium from other substances. Precious Metal Recycling The extracted ruthenium is usually in solution. A reducing agent is used to perform a reduction reaction with the ruthenium-containing solution to obtain ruthenium of higher purity. After the ruthenium is completely reduced and purified, the final step is usually to solidify or refine the ruthenium into a usable form through methods like heat treatment or electrolysis.

This concludes our discussion on the recovery of ruthenium dioxide. While sharing knowledge, we also hope to provide a deeper understanding of this process in the context of precious metals trading.

This post topic: Technology